BIM and VR Collaboration

As engineers, we’re pursuing virtual reality as a collaboration tool, creative solution and way to streamline the work we do each day.

3D technology and the integration of VR is transforming the AEC industry, giving architects, engineers, construction companies, and their clients better visibility and collaboration across projects. Early modeling avoids duplicated efforts and sets the project on a path to success. It allows for quick feedback and critical decisions to be made early, eliminating time spent on redesign efforts and ultimately providing project cost savings.

Whether it be live digital coordination sessions, colocated work groups, BIM clash detection, or virtual reality (VR) work sessions, our team is intentional about the technology we implement, electing the best-possible tools based on project, team and timeline.

We regularly host VR walk-throughs with our clients so they can experience this immersive technology for themselves. In the headset, the project is seen at a 1:1 ratio, allowing the viewer to discern whether the space feels restrictive, if the column spacing need to be adjusted, if material choices are correct, etc. This technology provides clients a realistic sense of the final product while creating opportunities for changes at a less costly stage in the project.

On many projects, we initiate the “clash detection process” and host entire teams to walk through complicated conditions on the screen or in VR. We realize that every clash resolved during design can prevent costly changes during construction, and strive to create an accurate and well-coordinated model.

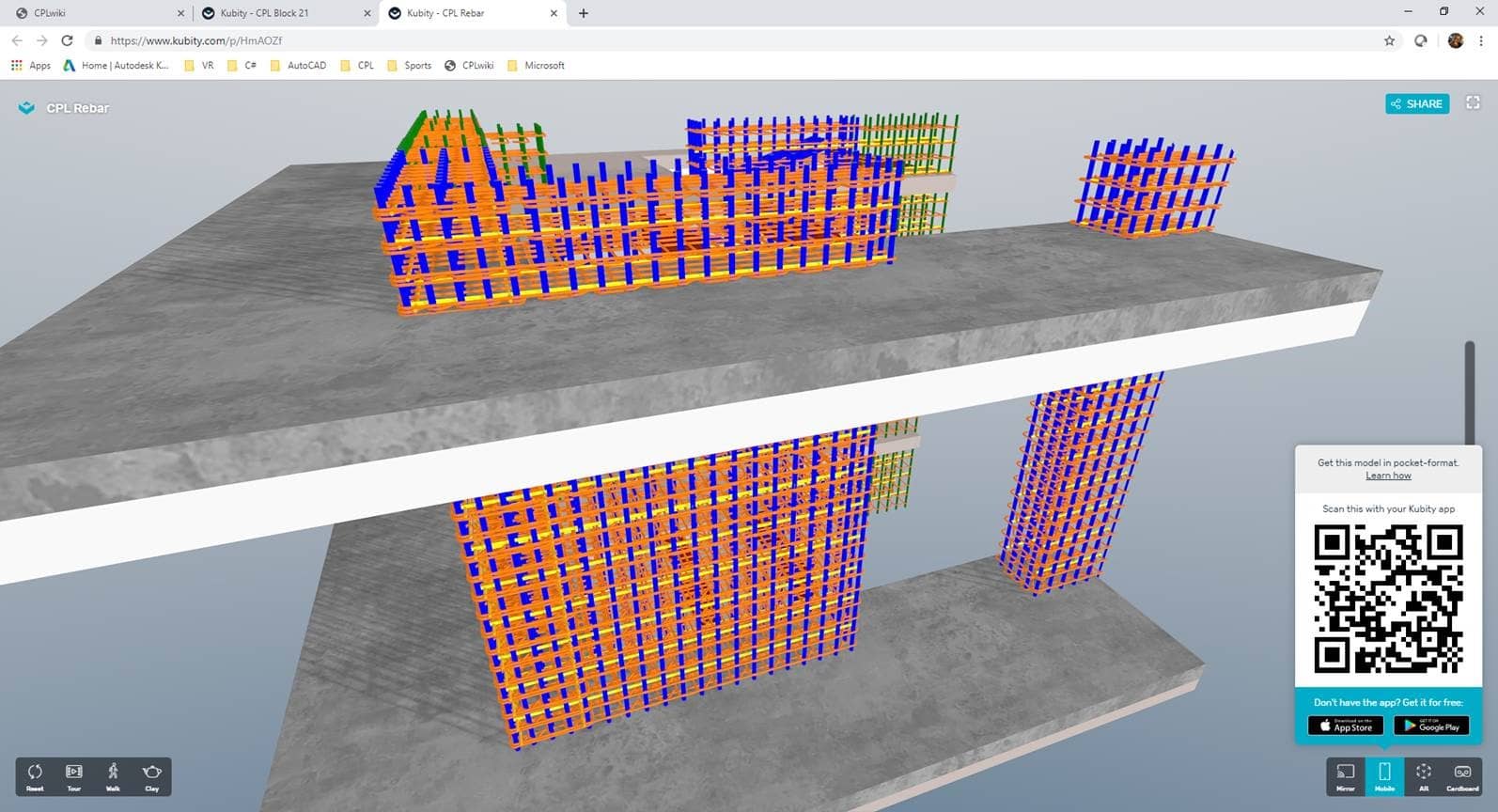

Now that most projects are paperless, designs, coordination and drawing development can happen live, and be pushed across all platforms. Kubity is one example of a 3D model-sharing application we use that can easily be downloaded on multiple devices, allowing users to share 3D models by scanning a dedicated QR code or by direct link. See it for yourself:

Kubity: 111 Westlake

Every piece of rebar in the shear core was modeled for 111 Westlake (Vulcan Block 48), allowing the team comprehensive 3D reviews. The team focused on congestion for incoming struts and prepared solutions for proposed MEP penetrations. This detailed information was used to cross-check quantities and pricing provided by the contractor, ensuring the material count was accurate.

Kubity: Amazon Block 21

Multiple coordination tools and methods were used throughout Amazon’s Block 21, synching plans with project team members. For a project of this scale, early planning with clear, precise 3D sketches was a must. Combined with live working sessions, the team was able to identify potential issues early on, create design solutions, and respond extraordinarily quickly.

Related Reading

Understanding Virtual Reality (and Leveraging it for AEC)

A VR101 crash course, we explore virtual reality basics and how the technology is being adapted for AEC.

A VR Hackathon Recap from our Technology Specialist

Coughlin Porter Lundeen Technology Specialist, Joel Hills, recounts his experience at Seattle’s Hackathon, where he and his team were given 48 hours to bring a VR concept from scratch to life.

Vulcan’s Holodome: We heard the buzz and had to try it!

Recapping our experience with the Holodome, Vulcan’s shared immersive reality exhibit at MoPOP.

Coughlin Porter Lundeen is leveraging VR for many live projects and regularly hosts in-office demos for clients. If you’re interested in a demo or learning how VR could be used for your project, please contact your project manager.